Lightweight and multifunctional, aluminium has become an essential commodity in the 21st century. With a variety of uses, ranging from as simple as packaging drinks to as complex as aeroplane components – one might argue that we now live in the Age of Aluminium.

This begs the question – how did we get here? Why is aluminium so prevalent in this day and age? For starters, it wasn’t always this way. At one point in history, it was considered a precious metal and even sold for prices higher than gold. It was only in the early 19th century that manufacturers came up with more efficient ways to extract and refine aluminium that it became more commonplace.

As time went on, the demand for low-cost malleable metals shot up as global consumer demand increased. One of the rare metals that aren’t impaired by recycling processes, aluminium costs become more manageable due to its environmental sustainability and reusability.

In Singapore, we can find aluminium used practically in all the things we see around us – from building construction to national infrastructure, and even in our homes.

In virtually every Build-To-Order (BTO) flat to the high rise office building, aluminium has become the default choice for crafting windows. Due to its hardy nature, it can be exposed to sunlight and rain without wear and tear over decades. Factor in the lightweight and craftable nature of the metal, there is a lesser burden of the weight on these taller buildings while allowing contractors to get creative with window patterns.

Playing off these same principles, aluminium becomes a staple in any industrial chain as a means of storage solutions. From racks to modular shelving, the sky’s the limit for how companies want to bend and mould their layouts for maximum efficiency. Its high strength to weight ratio has made it perfect for this exact use, and don’t be surprised to see aluminium shelves lining any warehouse you walk into in Singapore.

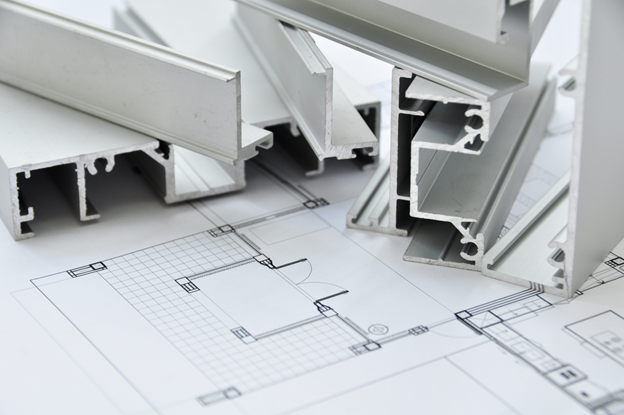

When it comes to anything that requires shaping, machining or customisation – aluminium is king. Using a process known as Computer Numerical Control (CNC) machining, manufacturers are able to employ computer software to guide machine tools precisely across the surface of metals. The result is a highly precise and accurate product. Compared to materials such as steel and its stainless cousin, aluminium is significantly easier to work with due to its tensile strength and malleability. It is also lighter than steel, which aids manufacturers in lowering production and transportation costs, passing these savings on to consumers.

A more common and less niche use of aluminium in engineering is vertical/horizontal milling, whereby excess material is cut from a blank slate of metal to obtain the desired outcome. Banking on the low waste factor and recyclable nature of aluminium, manufacturers are able to reuse the excess pieces as part of the next cycle of production. This makes for a green chain of production, with minimal environmental impact.

With Singapore’s history-making it the global port of call, it would be impossible to neglect the use of aluminium on ships. Specifically, the hulling and interior of shipping vessels. In the case of the former, we are referring to the exterior base of the ship. Historically, most cargo ships and large vessels were composed of steel for their low manufacturing costs and superior mechanical properties. As technology has advanced, current trends towards shipbuilding see non-heat-treatable aluminium alloys as the future. Although the upfront price weighs heavier on the wallet, these alloys are lighter and present more long-term gain due to savings in energy consumption. By reducing the overall weight of the ship itself, cargo vessels are able to increase their respective payload as well.

The final cherry on top of all of this is the environmental benefits aluminium presents – compared to fibreglass or steel, aluminium ships don’t necessarily end their life once condemned. In fact, aluminium alloy hulls find a new lease of life as they’re recycled and reincarnated into their next iteration of use.

Since 1965, TC Aluminium has been an industry cornerstone in providing an extensive and reliable selection of aluminium products. With unparalleled prices and top-notch delivery efficiency, solve all your aluminium needs with TC Aluminium, the leading aluminium supplier in Singapore, today.